Good Painting Procedures – Chapter 1: What is Paint?

Definition

A paint is a fluid which upon spreading over a surface (substrate) will dry into a continuous solid film.

What is the difference between a Paint and Coating?

• In principal, both are the same but Paint is more of a conventional / layman term for decorative application.

• Whereas, the term Coating is usually used by engineers / consultants as more sophisticated paint for heavy duty, marine and industrial application, such as factories, refineries, oil and gas & etc.

General Functions of Paint

When applied over substrates, paint will serve one or more of the following functions depending on its type

Decorative Function

Paints decorate by its colours, textures, finishes and its different levels of gloss.

Protective Function

Different paints offer protection to different types of substrates; depending on formulation, paints can protect against high humidity, chemical, oil, corrosion, algae, abrasion & etc.

Special Function

Paints can also be formulated for specific uses such as luminous paints for signs. Other types of paint formulated are Fire-Retardant paints, Anti-Condensation paints, Anti-Static paints, Cathodic Electro-Deposition (CED) paints & etc.

Properties of Paint

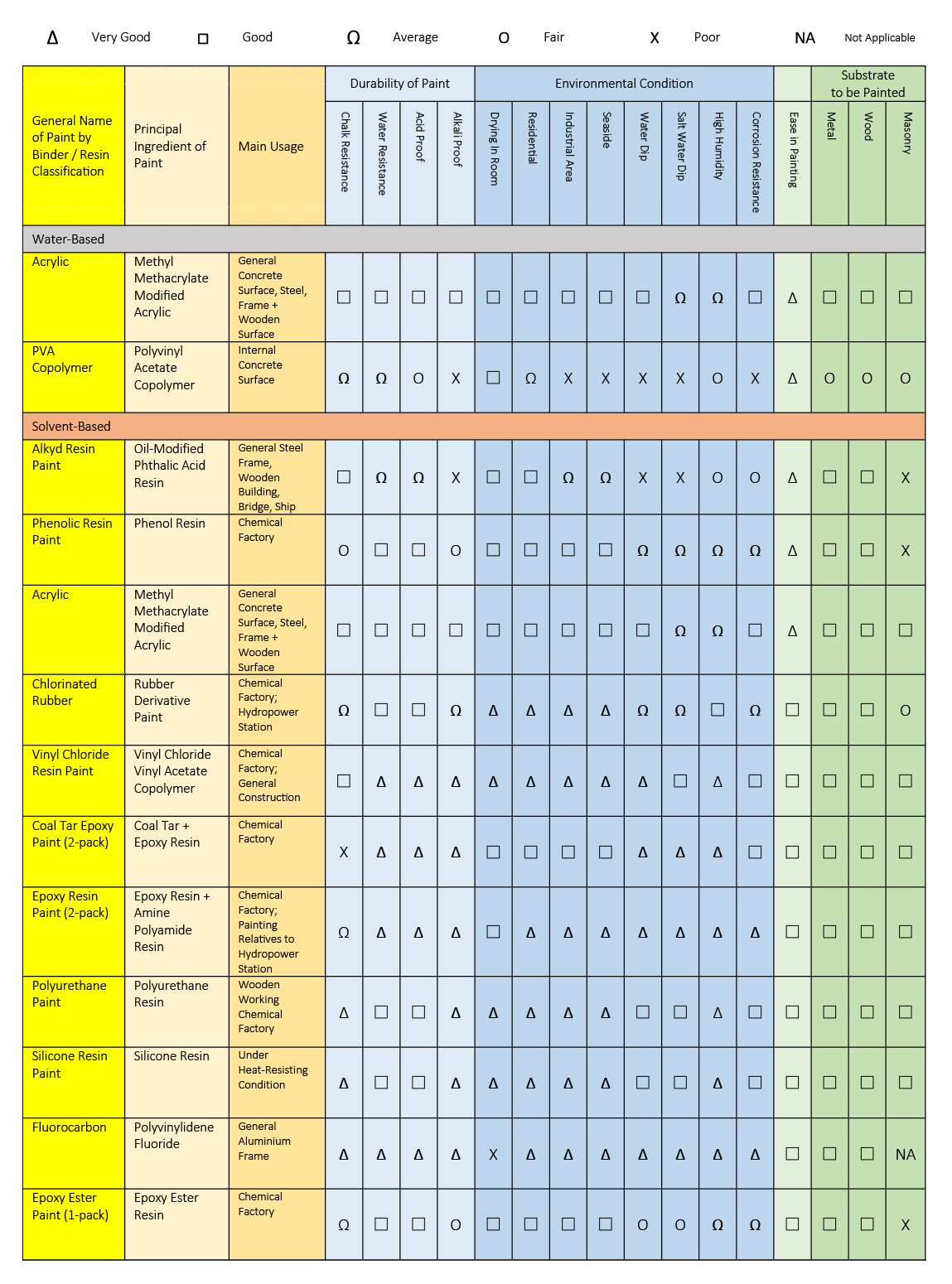

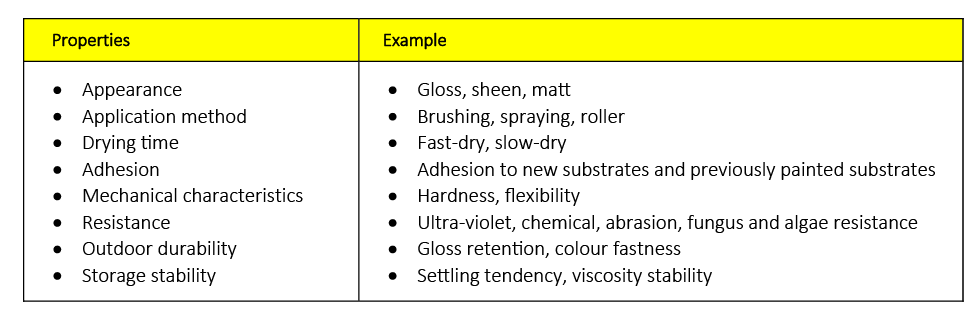

The essential and specific properties of paints may be classified as shown in Table 1 below:-

Composition of Paint

Paint is composed of the following ingredients:

Binders / Resins

This is the core of the paint. It forms the continuous layer of film and binds all pigments and other materials together in position. Binders are mainly responsible for the physical properties of the paint (e.g. appearance, adhesion, resistance). Examples of Binders / Resins: Polyvinyl Acetate (PVA), Alkyd, Phenolic, Acrylic, Epoxy, Polyurethane, Silicone & etc.

Pigments

Pigments are fine powder or flakes derived from organic (hydrocarbon) and inorganic (mineral ores) source and vary from 0.2 to 20 microns in size. Pigments are further categorised as below:-

True Pigments impart colours into the paint and have varying degree of hiding power. Examples of True Pigments: Titanium Dioxide, Red Oxide, Carbon Black & etc.

Extender Pigments have little or no opacity when mixed into paints. Their purpose is to impart body, assist in keeping opaque pigments in suspension, harden film and reduce costs. Examples of Extender Pigments: Calcium Carbonate, Talc, Baryte, Clay & etc.

Rust-inhibiting Pigments assist in chemical resistance, rust inhibition, and increases durability. Examples of Rust-inhibiting Pigments: Red Oxide, Zinc Chromate, Zinc Phosphate, Glass Flakes & etc.

Additives

These are remarkable ingredients which when added, normally in small dosage, have a profound influence on the physical and chemical properties of paint. They assist in easy processing of the paint, preventing possible defects during application, ensuring durability of paint and storage, stability & etc. Examples of Additives: Anti-Settling Agent, Anti-Skinning Agent, Anti-Foaming Agent, Anti-Fungus Agent, Flow and levelling & etc.

Solvents

These refer generally to any liquid that can dilute the paint. Such liquids help in the fluidity of paint and adjust viscosity to facilitate processing and application. They evaporate during the drying of paint to leave a solid film. Excessive thinning reduces gloss and density of the paint film. Examples of Solvents: Water, Organic Solvents such as Toluene, Ketone, Xylene, Turpentine & etc.

Classification of Paint

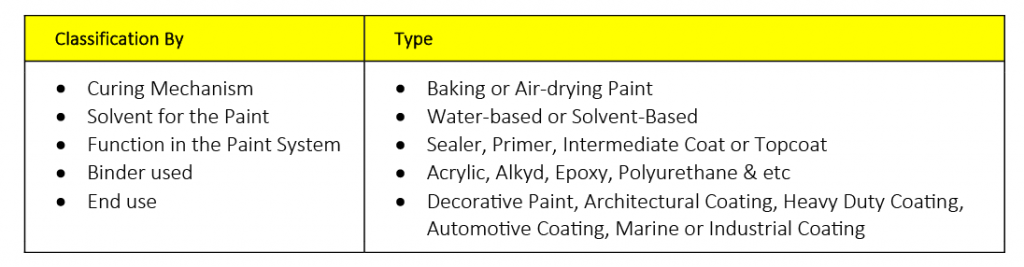

Generally, paints may be classified into the following types as in Table 2.

It is traditional to classify paints simply into either Emulsion or Enamel.

Emulsion paint is accepted as a water-based system that is dilutable with water, giving matt finish and commonly used for concrete and masonry surfaces. Enamel paint on the other hand is accepted as a solvent-based system that cab be diluted with solvent such as turpentine etc, giving a hard, gloss finish and normally used for wood and metal surfaces.

This method of paint classification has become out of date and unsuitable. Technological breakthrough within the paint industry have since created non solvent-based Enamel paints which are dilutable with water. Likewise, Emulsion paints with smooth, glossy enamel-like finish were also introduced into the market.

The traditional perception of Enamel paint as paint giving hard and glossy finish has now a misconception. There are many types of solvent-based paints like Acrylic, Polyurethane and Epoxy which all have similar gloss finish. These paints are made from different types of Binders and have different applications. Enamel normally refers only to the binder family Alkyd Resin which is generally used for wood and metal surfaces (Table 2A). Paints made of Polyurethane and Epoxy resins on the other hand can be used not only for wood and metal substrates, but also can be applied to masonry surfaces.

In view of such application versatility and appearance similarity of the new paints, it is imperative that the Binder / Resin component of the paint should be used for identification, e.g. Acrylic Emulsion, Alkyd Resin Enamel etc. As such, Table 2A sets out to classify paints by the Binder / Resin family, the solvent used and the general characteristics and properties of these paints.